Table of Contents

- A Brief Explanation of the JB Weld Steel Stick

- Understanding the Composition of JB Weld Steel Stick

- Step-by-Step Guide to Using JB Weld Steel Stick

- Advantages of Using JB Weld Steel Stick

- Common Applications of JB Weld Steel Stick

- Tips for Storage and Handling of JB Weld Steel Stick

- Troubleshooting and FAQs

- Conclusion

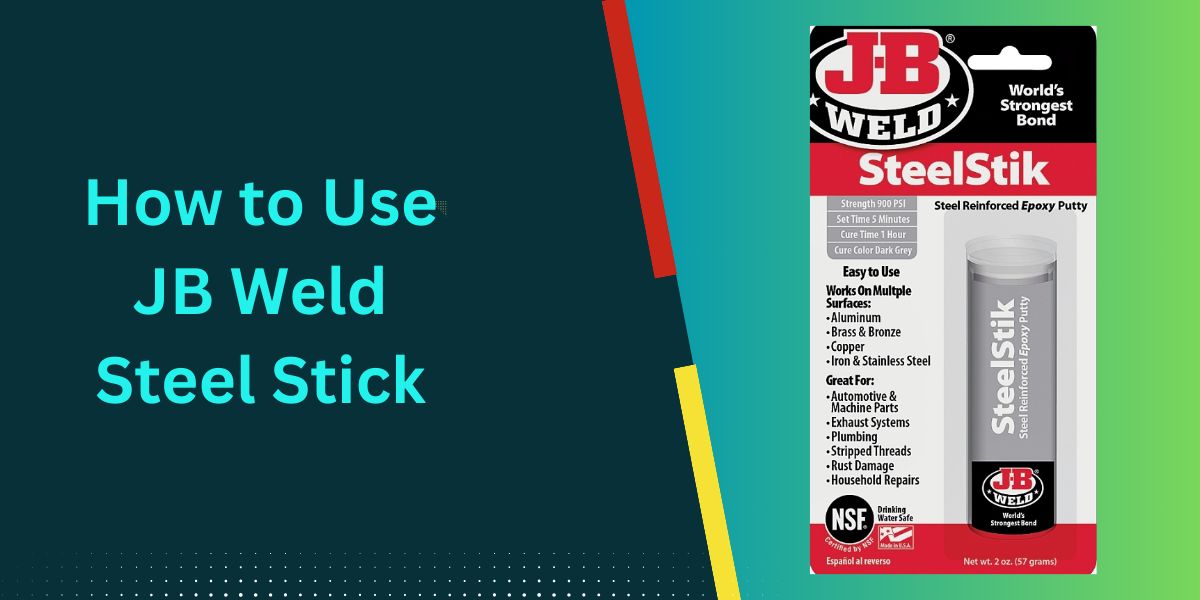

Unlock the secrets of how to use JB weld steel stick in this comprehensive guide! Discover how this adhesive stands out from its powerhouse composition to step-by-step application tips. We’ll navigate its advantages, diverse applications, and comparisons, empowering you to wield JB Weld Steel Stick like a pro.

Whether you’re a DIY wizard or a repair enthusiast, this article gives you the know-how for flawless, enduring fixes. Dive in and master the art of JB Weld Steel Stick for your toughest repair challenges!

A Brief Explanation of the JB Weld Steel Stick

JB Weld Steel Stick is a reliable and versatile adhesive solution for repairs. It’s renowned for its exceptional bonding capabilities across various materials, making it a go-to choice for DIY enthusiasts and professionals.

Versatility and Reliability

What sets JB Weld Steel Stick apart is its ability to adhere to multiple surfaces with remarkable efficacy. Whether metal, plastic, ceramic, or other materials, this adhesive demonstrates consistent and robust bonding, providing users with a versatile solution for various repair needs.

Efficacy in Adverse Conditions

One of the standout features of JB Weld Steel Stick is its resilience in adverse conditions. It remains effective even under extreme temperatures, making it suitable for repairs in environments that experience high heat or extreme cold.

Ease of Use

Beyond its adhesive prowess, the JB Weld Steel Stick is user-friendly. Its simple application process and reliable bonding properties make it accessible to individuals tackling repairs without extensive technical expertise.

Cost-Effectiveness

Another appealing aspect of JB Weld Steel Stick is its cost-effectiveness. Offering a reliable alternative to expensive replacements or professional repairs enables individuals to save time and money by effectively fixing items themselves.

Trusted Reputation

Over time, JB Weld Steel Stick has earned a reputation for reliability and durability. Its consistent performance in various repair scenarios has established it as a trusted adhesive among DIY enthusiasts, hobbyists, mechanics, and professionals across different industries.

In essence, JB Weld Steel Stick introduces itself as a dependable adhesive solution, catering to the diverse needs of users seeking a reliable, versatile, and cost-effective way to address repairs in different settings. Its ease of use, resilience, and proven track record make it a staple in many toolkits.

Understanding the Composition of JB Weld Steel Stick

JB Weld Steel Stick is a remarkable adhesive renowned for its strength and versatility. To comprehend its efficacy, it’s essential to delve into its composition, which comprises two primary components: epoxy resin and hardener, combined with a steel-reinforced formula.

Epoxy Resin and Hardener

Epoxy resin, a thermosetting polymer, is the foundation of JB Weld Steel Stick’s adhesive properties. A chemical reaction occurs when blended with a hardener, triggering the curing process. This reaction initiates the transformation of the mixture into a solid, creating a powerful bond known for its exceptional adhesion across various materials.

The key to unlocking the full potential of JB Weld Steel Stick lies in the accurate mixing of equal parts of epoxy resin and hardener. This precise blending ensures the formation of a potent and durable adhesive bond.

Steel-Reinforced Formula

What elevates JB Weld Steel Stick’s performance is its steel-reinforced formula. This unique formulation introduces steel particles into the epoxy resin and hardener mixture, augmenting the adhesive’s strength and structural integrity.

The addition of steel imparts remarkable tensile strength and durability to the JB Weld Steel Stick, making it particularly effective for repairs requiring resilience and lasting solutions.

When these components amalgamate, they create a robust adhesive capable of withstanding substantial stress and offering steadfast adhesion on many surfaces, from metals to plastics and ceramics.

Understanding the intricate chemistry behind the composition of JB Weld Steel Stick empowers users to harness its adhesive properties effectively. This comprehension enables individuals to execute repairs confidently, knowing they’re employing an adhesive renowned for its reliability, strength, and versatility across diverse repair applications.

Step-by-Step Guide to Using JB Weld Steel Stick

Mastering the application of JB Weld Steel Stick involves a systematic approach that ensures optimal bonding and lasting results. Here’s a detailed guide outlining the steps for using this versatile adhesive effectively:

Surface Preparation

Start by preparing the surfaces intended for bonding. Ensure they are clean, dry, and free from any contaminants such as dirt, grease, rust, or paint. Abrade or roughen smooth surfaces slightly to enhance adhesion. Cleaning the surfaces thoroughly is crucial to achieving a strong bond.

Mixing the Steel Stick

Carefully knead and mix equal parts of the epoxy resin and hardener. Precision in mixing is vital to activate the chemical reaction that initiates the curing process. Blend the components until a uniform colour and consistency are achieved. This ensures the formation of a strong and reliable bond.

Application Techniques

Apply the mixed JB Weld Steel Stick onto the prepared surface. Use a suitable tool, such as a putty knife or gloved fingers, to spread the adhesive evenly. Ensure complete coverage of the bonding area with a consistent adhesive layer. Pay attention to specific instructions on the product packaging regarding application thickness or technique.

Curing Process

Allow sufficient time for the adhesive to cure. Follow the manufacturer’s recommended curing time and environmental conditions, such as temperature and humidity, for optimal results. It’s crucial to avoid disturbing or stressing the bond during the curing period to ensure its strength and durability.

Final Touches

After the recommended curing period, the JB Weld Steel Stick should have hardened and formed a strong bond. Any excess adhesive can be trimmed or shaped as needed once it has fully cured. If required, sanding or painting over the cured adhesive is possible, allowing for a finished appearance or further refinements.

Mastering these steps using JB Weld Steel Stick ensures adequate bonding and durable repairs across various materials and applications. Adhering to proper surface preparation, accurate mixing, precise application, and sufficient curing time are crucial elements in achieving successful outcomes with this versatile adhesive.

Advantages of Using JB Weld Steel Stick

JB Weld Steel Stick offers many advantages, making it a preferred choice for bonding and repairs in various settings. Understanding these advantages highlights the reasons behind its popularity among users:

Versatility

One of the standout features of JB Weld Steel Stick is its versatility. It exhibits remarkable adhesion across various materials, including metals, plastics, and ceramics. This adaptability allows users to address diverse repair needs without the limitation of material compatibility, making it a versatile solution for different projects.

Strength and Durability

The steel-reinforced formula of JB Weld Steel Stick provides exceptional strength and durability. It creates bonds that withstand significant stress and environmental conditions, ensuring long-lasting and resilient repairs. Whether fixing cracks in metal components or reinforcing weakened structures, the adhesive delivers robust results.

Resilience to Adverse Conditions

JB Weld Steel Stick maintains its efficacy even in adverse conditions. It is resistant to high temperatures, making it suitable for repairs in environments exposed to heat or extreme weather conditions. Its resilience ensures that repairs remain intact and effective, even under challenging circumstances.

Easy Application

Another notable advantage of JB Weld Steel Stick is its user-friendly application. The simple mixing process and easy-to-apply nature make it accessible to users with varying levels of expertise. Its user-friendly design empowers individuals to execute repairs efficiently and effectively without requiring specialized skills or equipment.

Cost-Effectiveness

JB Weld Steel Stick offers a cost-effective solution by providing a reliable alternative to costly replacements or professional repairs. Users can address repair needs themselves, saving time and money while achieving dependable results. Its affordability, coupled with its effectiveness, makes it a practical choice for budget-conscious consumers.

Common Applications of JB Weld Steel Stick

JB Weld Steel Stick finds extensive use across various domains owing to its robust bonding capabilities and versatility. Here are some common applications where this adhesive excels:

Automotive Repairs

In the automotive industry, JB Weld Steel Stick is a reliable solution for repairing cracked engine components, sealing leaks in exhaust systems, fixing metal parts, and addressing many automotive repair needs. Its ability to withstand high temperatures and provide durable bonds makes it invaluable for mechanics and car enthusiasts.

Household Fixes

Within households, JB Weld Steel Stick is handy for fixing metal fixtures, patching up plumbing leaks, repairing appliances, and addressing various household repair requirements. Its versatility allows for dependable fixes in different materials commonly found in homes.

Industrial Use

Industrially, JB Weld Steel Stick finds applications in repairing machinery, equipment, and structural components. Its strength and durability make it suitable for reinforcing, repairing, or bonding various materials used in industrial settings, contributing to efficient maintenance practices.

Crafting and DIY Projects

For crafters and DIY enthusiasts, JB Weld Steel Stick opens doors to creative projects. Its ability to bond different materials allows for assembling diverse objects, making it a valuable tool in crafting and DIY endeavours.

Marine Repairs

Given its resistance to water and ability to form a waterproof bond, JB Weld Steel Stick is a preferred choice for marine repairs. It effectively seals leaks in boats, fixes metal parts, and addresses maintenance needs in marine environments.

Emergency Repairs

JB Weld Steel Stick is a reliable, quick, and effective emergency repair solution. Its versatility and strong bonding properties make it an ideal temporary fix until a permanent solution can be implemented.

The adaptability of JB Weld Steel Stick across various applications underscores its versatility and reliability in addressing repair needs in different settings. This adhesive is a dependable solution for bonding and repair requirements in automotive, household, industrial, crafting, marine, or emergency contexts.

Tips for Storage and Handling of JB Weld Steel Stick

Proper storage and handling of JB Weld Steel Stick are crucial for maintaining its effectiveness and extending its shelf life. Here are essential tips to ensure optimal storage and safe handling:

Storage Conditions

- Cool and Dry Environment: Store JB Weld Steel Stick in a cool, dry place away from direct sunlight or heat sources. Exposure to high temperatures can affect its performance and shelf life.

- Seal the Container: Always tightly seal the container after use to prevent air exposure, which can cause the adhesive to harden prematurely.

- Avoid Freezing: While the JB Weld Steel Stick is resilient, freezing temperatures may impact its consistency. Please protect it from freezing by storing it in a temperature-controlled environment.

Safety Precautions

- Use Protective Gear: Wear gloves and protective eyewear to prevent skin contact and eye irritation when handling JB Weld Steel Stick.

- Adequate Ventilation: Work in a well-ventilated area to minimize exposure to fumes. This ensures a safer working environment.

- Avoid Contact with Skin: In case of skin contact, wash the affected area thoroughly with soap and water. Use a suitable hand cleaner to remove residues from the skin.

- Clean Tools Promptly: After use, clean tools and surfaces that come into contact with the adhesive to prevent hardening and ensure they remain usable for future applications.

Shelf Life

- Check Expiry Dates: Always check the expiration date on the packaging before use. JB Weld Steel Stick typically has a shelf life of several years when stored correctly.

- Discard Old or Expired Product: Avoid using JB Weld Steel Stick beyond its expiration date. Old or expired adhesive may not perform as intended, compromising the quality of repairs.

Adhering to these storage and handling practices ensures that JB Weld Steel Stick remains effective, prolongs its shelf life, and maintains its adhesive properties. By following these guidelines, users can maximize the usability and performance of this versatile adhesive for various repair applications.

Comparing JB Weld Steel Stick with Other Adhesives

Understanding how JB Weld Steel Stick stands out compared to other adhesives helps users decide on the best adhesive for their needs. Here’s a comparative analysis:

Strength Comparison

- JB Weld Steel Stick: This adhesive boasts exceptional strength due to its steel-reinforced formula. It provides robust and durable bonds across various materials, making it suitable for demanding applications requiring high strength and resilience.

- Epoxy Adhesives: Traditional epoxy adhesives also offer strong bonds, but JB Weld Steel Stick, with its steel-infused composition, tends to outperform standard epoxies in sheer strength and durability.

- Super Glue (Cyanoacrylate): While super glue offers quick bonding, it may not match the strength and durability of the JB Weld Steel Stick, especially in scenarios requiring substantial tensile strength.

Application Scenarios

- Specialized Adhesives: Certain adhesives cater to specific materials or applications. For instance, wood glue is tailored for wood surfaces, while some adhesives work best with plastics or ceramics. JB Weld Steel Stick, however, exhibits versatility across a wide range of materials.

- Quick-Setting Adhesives: Some adhesives are set rapidly, enabling quick fixes. JB Weld Steel Stick, while not as instantaneous, provides a robust bond with ample curing time, ensuring a reliable and long-lasting repair.

Durability and Versatility

- Weather and Temperature Resistance: JB Weld Steel Stick demonstrates resilience in varying conditions, including resistance to high temperatures and harsh environments, making it suitable for indoor and outdoor repairs.

- Longevity of Bond: The steel-reinforced composition of JB Weld Steel Stick often results in a longer-lasting bond than other adhesives, especially in scenarios involving continuous stress or exposure to elements.

Troubleshooting and FAQs

Common Issues and Solutions

- Incomplete Bonding: If the bonding seems incomplete, it might be due to inadequate surface preparation. Ensure surfaces are clean, dry, and roughened adequately for optimal adhesion. Also, verify that the adhesive was mixed thoroughly and applied evenly.

- Curing Problems: Issues with curing can occur if the adhesive is applied in conditions outside the recommended temperature or humidity range. Follow the manufacturer’s instructions for ideal curing conditions. In case of slower curing, extend the curing time accordingly.

- Weak Bond: Weak bonds may result from improper mixing ratios or insufficient adhesive applied to the surfaces. Double-check the mixing process and apply sufficient adhesive to ensure a strong bond.

video by Field Guide to DIY with Eddie Field

Conclusion

In conclusion, mastering the usage of JB Weld Steel Stick opens a world of possibilities for seamless and enduring repairs. From its robust composition to its versatile applications across various materials, this adhesive is a reliable solution. Armed with the insights gained from this guide, whether you’re tackling automotive fixes, household repairs, or industrial maintenance, you’re equipped to leverage the strength and versatility of JB Weld Steel Stick for successful and long-lasting results.

Can JB Weld Steel Stick be used on surfaces exposed to high temperatures?

Yes, JB Weld Steel Stick can withstand temperatures up to a specific range, usually indicated on the packaging. Ensure that its heat resistance is checked before application.

Is it possible to sand or paint over cured JB Weld Steel Stick?

Yes, once cured, JB Weld Steel Stick can be sanded, shaped, drilled, tapped, machined, and painted.

What is the shelf life of JB Weld Steel Stick?

When stored under proper conditions, JB Weld Steel Stick typically has a shelf life of a few years.

Can JB Weld Steel Stick be used on plastic surfaces?

Yes, it adheres well to various materials, including plastics. However, proper surface preparation is crucial for optimal bonding.

Is JB Weld Steel Stick waterproof?

Yes, once cured, it creates a waterproof and resistant bond.

1 thought on “How to Use JB Weld Steel Stick”