Table of Contents

- Introduction to Underwater Welding

- The Underwater Welding Process

- Factors Affecting Welding Duration

- Time Limits for Underwater Welding

- Technological Advancements

- Challenges and Risks

- Achievements in Underwater Welding

- How Many Years Can You Do Underwater Welding?

- Can Welding Be Done Underwater?

- How Deep Can You Weld Underwater?

- How Long Do Oil Rig Divers Stay Underwater?

- Embracing Possibilities: A Brighter Future for Underwater Welding

- FAQs – About How Long Can You Weld Underwater

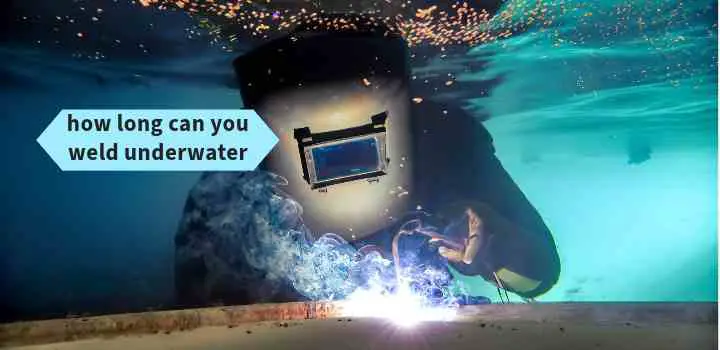

Diving into the world of underwater welding, we uncover the challenges, techniques, and remarkable feats accomplished beneath the waves. Underwater welding is a highly specialized field that demands a unique set of skills and equipment due to the challenging environment it takes place. In this article, we’ll delve into the intricacies of underwater welding, the time constraints faced by welders, and the factors that affect the duration of welding beneath the surface.

Introduction to Underwater Welding

How Long Can You Weld Underwater

Welding underwater is a fascinating and challenging process that plays a crucial role in various industries such as offshore construction, shipbuilding, and underwater repair. The ability to perform welding tasks beneath the water’s surface is essential for maintaining structures, pipelines, and equipment that are submerged. In this article, we’ll delve into the intricacies of underwater welding, its techniques, challenges, and the factors that influence the duration of welding operations beneath the waves.

The Underwater Welding Process

Preparations and Safety Measures

Before embarking on an underwater welding project, thorough preparations are essential. Welders must be certified and well-trained in both welding techniques and diving. Safety measures, such as proper equipment checks, understanding water currents, and communication protocols, are critical to mitigate potential risks.

Methods of Underwater Welding

Two primary methods dominate underwater welding: dry welding and wet welding.

Dry Welding

Dry welding involves creating an enclosed chamber around the welding area, effectively isolating it from the surrounding water. This method ensures that the welding process takes place in a dry and controlled environment. While it provides optimal conditions for welding, setting up the chamber can be complex and time-consuming.

Wet Welding

Wet welding, on the other hand, involves performing the welding directly underwater. This method demands a high level of skill due to the challenges posed by the surrounding water, such as temperature, pressure, and the conductive properties of the water itself.

Factors Affecting Welding Duration

Depth and Pressure

As a diver descends into the depths, pressure increases significantly. This impacts the welding process by affecting the arc stability, electrode consumption, and the weld pool’s behavior. Welders need to adjust their techniques to counteract these effects.

Temperature and Material

Water temperature plays a vital role in underwater welding. Colder waters can accelerate the cooling of the weld, potentially affecting its quality. The type of material being welded also influences the process. Some metals are more challenging to weld underwater due to their composition.

Welding Techniques

The choice of welding technique impacts the duration and quality of the weld. Techniques like shielded metal arc welding (SMAW) and flux-cored arc welding (FCAW) are commonly used, each with its own advantages and limitations.

Time Limits for Underwater Welding

Standard Working Hours

Underwater welders often adhere to a schedule similar to that of surface welders, working around 6-8 hours a day. However, the challenging environment and physical demands mean that even this shorter duration can be exhausting.

Extended Welding Sessions

In situations where immediate repairs are required, extended welding sessions might be necessary. These sessions involve careful management of diver fatigue and maintaining optimal conditions for welding.

Technological Advancements

Hyperbaric Welding

Hyperbaric welding involves creating a sealed chamber around the welding area and filling it with a gas mixture, often helium-based. The increased pressure within the chamber allows for a stable environment, reducing the impact of water on the welding process. This technique is highly effective for critical repairs and projects where precision is paramount. Hyperbaric welding minimizes the risks associated with water exposure and provides a controlled atmosphere for welders to work in.

Remote Operated Vehicles (ROVs)

The integration of technology has led to the development of remote-operated vehicles (ROVs), which have revolutionized underwater welding. These remotely controlled machines are equipped with welding equipment and cameras, allowing welders to operate from a distance. ROVs are particularly valuable for tasks that are too hazardous, deep, or challenging for human divers. They provide real-time visual feedback, precise control, and a safer working environment for complex underwater welding projects.

Challenges and Risks

Diver Fatigue

Working underwater, especially at significant depths, is physically demanding. Divers experience increased fatigue due to the cold temperature, high pressure, and the need to carry heavy equipment. Prolonged exposure to these conditions can impact the quality of welding and the safety of the diver. Proper training, frequent breaks, and rotational work schedules are implemented to manage diver fatigue effectively.

Corrosion and Contaminants

The underwater environment is harsh on metals, accelerating the process of corrosion. Welded joints are susceptible to corrosion, compromising the structural integrity of underwater installations. Contaminants present in the water, such as sediment and minerals, can also affect the welding process. Welders must employ techniques to mitigate these challenges, such as using specialized materials and coatings to enhance the durability of the welds.

Achievements in Underwater Welding

Subsea Repairs

Underwater welding has enabled significant achievements in the realm of subsea repairs. Repairing critical infrastructure such as oil and gas pipelines, offshore platforms, and ship hulls without the need for dry docking has saved both time and resources. The ability to carry out repairs underwater ensures the continued functionality of vital structures without disrupting operations.

Offshore Installations

The construction of offshore installations, including wind farms, oil rigs, and marine structures, relies heavily on underwater welding. Welders play a crucial role in securing these installations against the forces of nature, ensuring their stability and durability in the harsh marine environment. Their work contributes to the expansion of renewable energy sources and the extraction of valuable resources from the sea.

How Many Years Can You Do Underwater Welding?

Embarking on a Long-Lasting Career Beneath the Waves

Underwater welding isn’t just a profession; it’s a calling that beckons those with a passion for both welding and the aquatic world. A typical career in underwater welding can span anywhere from 10 to 25 years, depending on factors like physical fitness, expertise, safety measures, and the individual’s risk tolerance. This occupation offers a unique blend of technical skill, physical prowess, and mental fortitude, making it an exciting and enduring choice for many.

Can Welding Be Done Underwater?

Navigating the Challenges of Submerged Welding

Indeed, welding can be performed underwater, but the process is far more intricate and demanding than conventional welding. Underwater welding comes in two primary methods: wet welding and dry welding. Wet welding involves working directly in the water using specially designed electrodes, while dry welding necessitates a hyperbaric chamber to create a dry environment around the welder. Both methods require specialized training, equipment, and precautions due to the complexities of working in the underwater environment.

How Deep Can You Weld Underwater?

Plunging into the Depths of Subsea Welding

The depth at which underwater welding can be conducted is an area of considerable interest. While various factors like water pressure, visibility, and safety concerns play a role, skilled underwater welders can operate effectively at depths of up to 300 meters (984 feet). Beyond that, the extreme pressure and hazardous conditions become formidable challenges that demand even more advanced technology and training.

How Long Do Oil Rig Divers Stay Underwater?

Unveiling the Tenacity of Offshore Divers

Oil rig divers, the unsung heroes of offshore exploration, display remarkable endurance while working beneath the ocean’s surface. The duration oil rig divers spend underwater varies based on the task and diving method. Saturation divers, who work in pressurized environments, can stay submerged for several weeks, even up to a month, while carrying out intricate tasks like maintenance, construction, and repair on oil rigs. Surface-supplied divers, on the other hand, generally have shorter dive times, ranging from 1 to 6 hours, due to logistical constraints.

Embracing Possibilities: A Brighter Future for Underwater Welding

In conclusion, the question of how long one can weld underwater is being redefined by innovative breakthroughs. The marriage of technology, materials science, and training advancements is ushering in an era of extended welding durations. As we dive deeper into the potential of hyperbaric chambers, advanced electrodes, and cutting-edge alloys, the barriers that once constrained underwater welding are steadily eroding.

So, whether it’s the depths of the ocean floor or the intricacies of welding beneath the waves, the human spirit of innovation knows no bounds. As we continue to unlock the potential of underwater welding, we are not only expanding our technical capabilities but also honoring the spirit of exploration that drives us to push the limits of what is achievable in the underwater realm.

FAQs – About How Long Can You Weld Underwater

Q1. Is underwater welding dangerous?

Answer: Underwater welding carries inherent risks due to the challenging environment, pressure, and potential exposure to contaminants. Proper training and safety measures are crucial.

Q2. Can anyone become an underwater welder?

Answer: Not anyone can become an underwater welder. It requires specialized training, certifications, and physical fitness to withstand the demands of the job.

Q3. How deep can underwater welders work?

Answer: The depth at which underwater welders can work depends on their training, equipment, and the specific conditions of the project. Some welders can operate at considerable depths.

Q4. What is hyperbaric welding?

Answer: Hyperbaric welding involves welding in a chamber filled with gas at a higher pressure than the surrounding water. This method offers better control and safety during underwater welding.

Q5. Are there alternatives to human divers for underwater welding?

Answer: Yes, remote-operated vehicles (ROVs) are used for underwater welding in situations where human access is limited or hazardous, providing a safer and more controlled environment for welding.

5 thoughts on “How Long Can You Weld Underwater? Exploring the Depths”